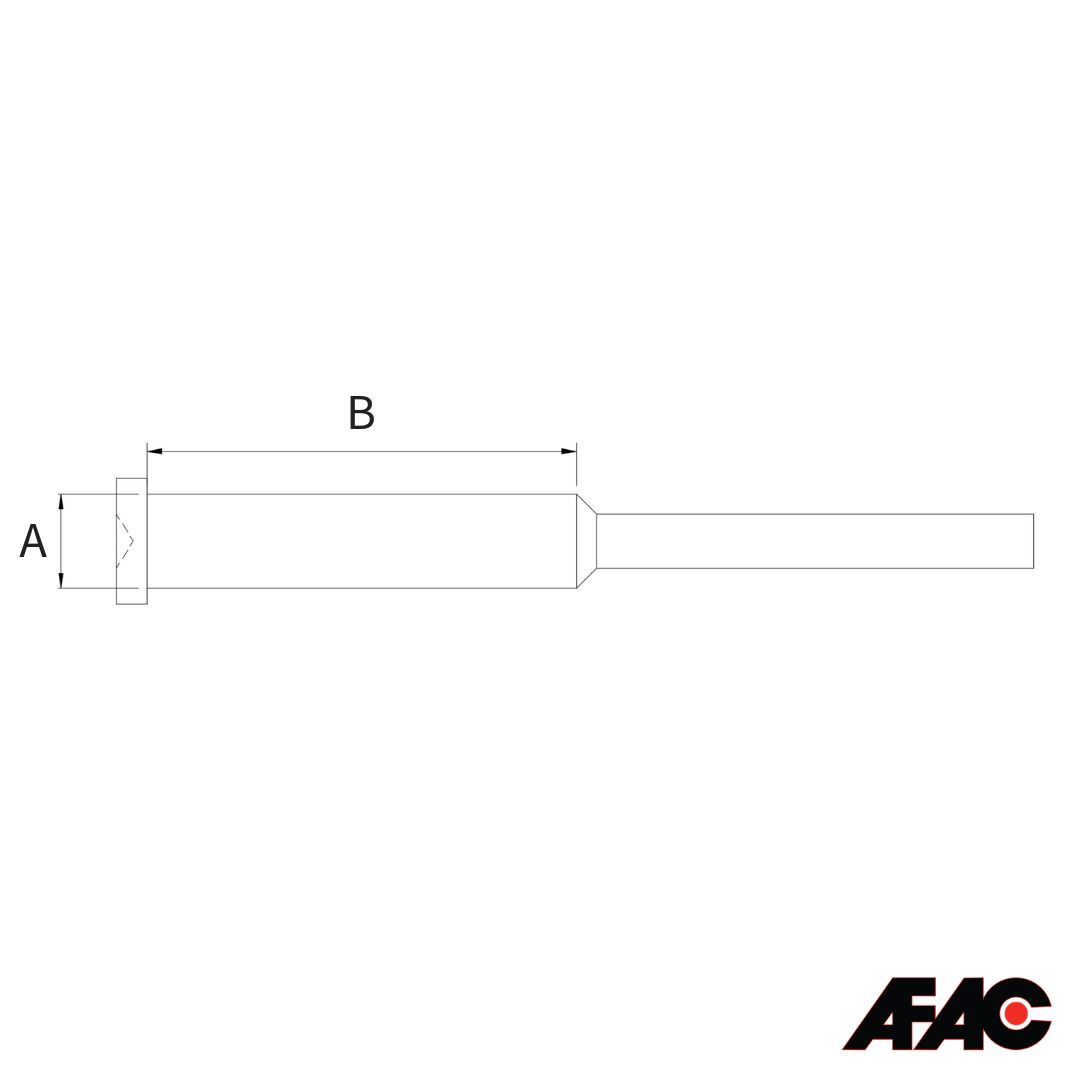

Weld Nut Plug – Silicone Rubber

AFAC’s Weld Nut Plug is a pull through plug with a circular feature offering the option to protect a small area around the hole it is being used to mask. This is favourable on weld nuts where often the coating being applied is thicker. Weld nuts that are masked with weld nut plugs provide a better quality of finish and easier assembly once finished.

Used for:

- Powder coating

- Anodising

- Electroplating

- Hydrodipping

Next day delivery

Whatever purpose you want hollow bungs for, there are tons of options and most are in stock for next day delivery.

| Part Number | "A" (mm) | "B" (mm) | Colour | Fits | Add to Cart |

|---|---|---|---|---|---|

| NTR-04.39-25LL | 4.39 | 25.40 | Lilac | M5 | £0.45Add to basket |

| NTR-05.54-25BK | 5.54 | 25.40 | Black | M6 | £0.45Add to basket |

| NTR-05.84-25GY | 5.84 | 25.40 | Grey | M6 | £0.45Add to basket |

| NTR-07.24-25WH | 7.24 | 25.40 | White | M8 | £0.45Add to basket |

| NTR-07.24-25YW | 7.24 | 25.40 | Yellow | M8 | £0.45Add to basket |

| NTR-08.89-25BN | 8.89 | 25.40 | Brown | M10 | £0.21Add to basket |

| NTR-10.67-25GY | 10.67 | 25.40 | Grey | M12 | £0.32Add to basket |

| NTRL-07.24-25WH | 07.24 | Custom | White | Custom | £0.19Add to basket |

| NTRL-10.45-40LB | 10.45 | 40.00 | Light Blue | Custom | £0.45Add to basket |

The weld nut plug is a simple design that provides customers with a device to mask threaded through holes like weld nuts. A snug fit either end and a lip that helps improve assembly efficiency.

| Part No | Fits | ‘A’ mm | ‘B’ mm | ‘C’ mm | Colour | Purchase Here |

|---|---|---|---|---|---|---|

| NTR-04.39-25LL | M5 | 4.39 | 2.49 | 6.35 | Lilac | |

| NTR-05.33-12BK | M6 | 5.33 | 3.30 | 9.14 | Black | |

| NTR-05.54-25BK | M6 | 5.54 | 3.18 | 8.64 | Black | |

| NTR-05.84-25CL | 1/4 UNF | 5.84 | 3.18 | 8.89 | Clear | |

| NTR-07.24-25WH | M8 | 7.24 | 4.06 | 10.16 | White | |

| NTR-08.51-25CL | 3/8 UNC | 8.51 | 4.06 | 11.68 | Clear | |

| NTR-08.89-25BN | M10 | 8.89 | 4.75 | 12.01 | Brown | |

| NTR-10.67-25GY | M12 | 10.67 | 5.97 | 13.72 | Grey | |

| NTR-11.30-25CL | 1/2 UNF | 11.30 | 6.10 | 14.22 | Clear | |

| NTR-12.45-25CL | 9/16 UNC | 12.45 | 6.48 | 15.49 | Clear |

Silicone Rubber Weld Nut Plug – The Material

Manufactured from silicone rubber, Silicone Rubber Weld Nut Plug or BAKEWELL NUTTER PLUG are ideal for masking during electro-static powder coating, stove enamelling, E-Coat, plating and anodising.

They will also resist extreme cold without deterioration, in industrial and laboratory applications.

If you have a hole to fill that the sizes listed don’t cover, give us a call. There’s loads of stuff we can supply that isn’t listed. AFAC technicians are on hand to help you solve your plugging and capping issues. Customers can call us during office hours for assistance.

With millions of parts on the shelf, AFAC offers customers a variety of choices to suit most masking applications. As well as the stock lines, AFAC also produces custom made mouldings, extrusions and self adhesive shapes. With customers all over the country and around the World, AFAC can be relied on to deliver quality products at affordable prices for any size of business.

As well as high temperature masking supplies, AFAC also offers wet-spray friendly masking products made using EPDM rubber.