Description

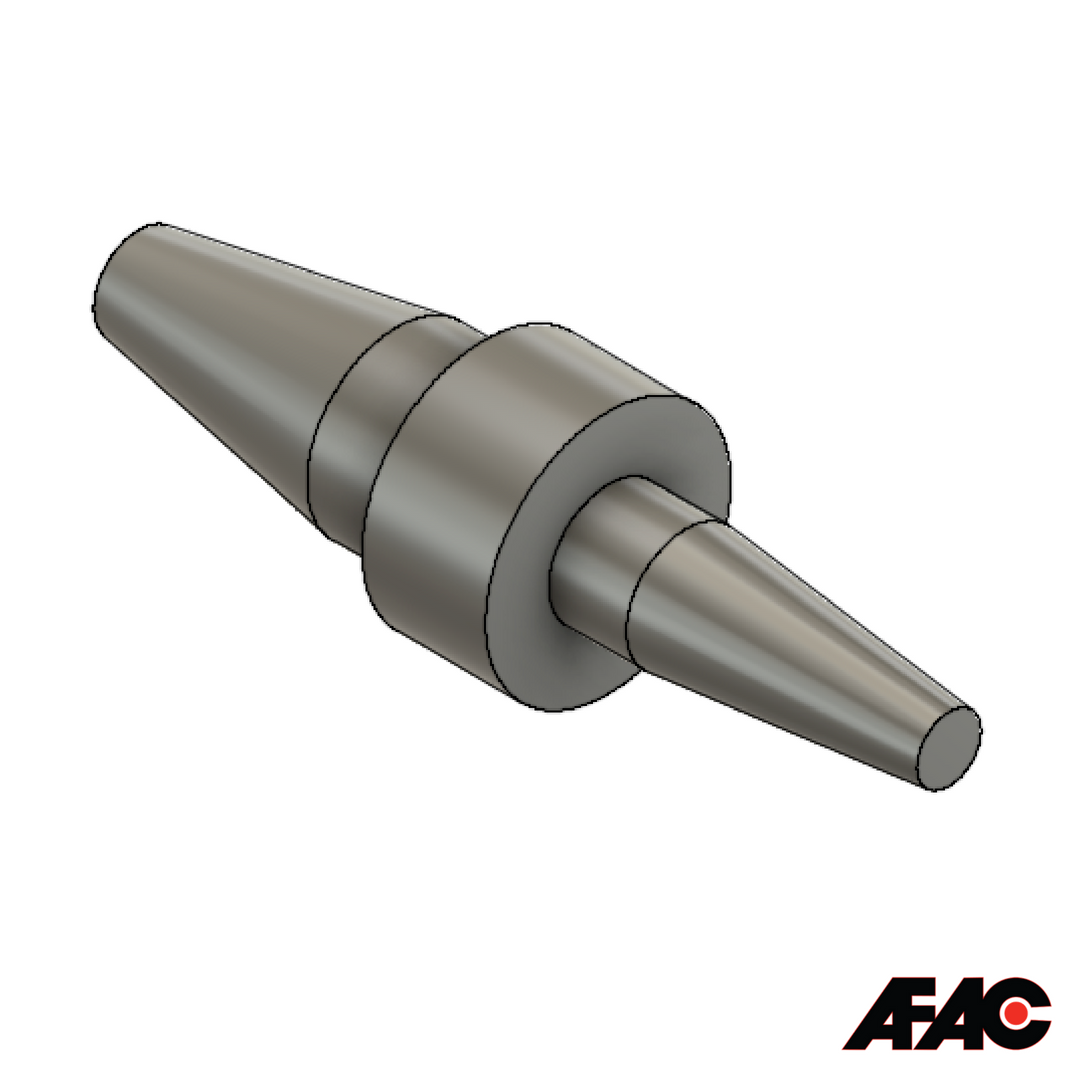

The washer plug from AFAC Ltd.

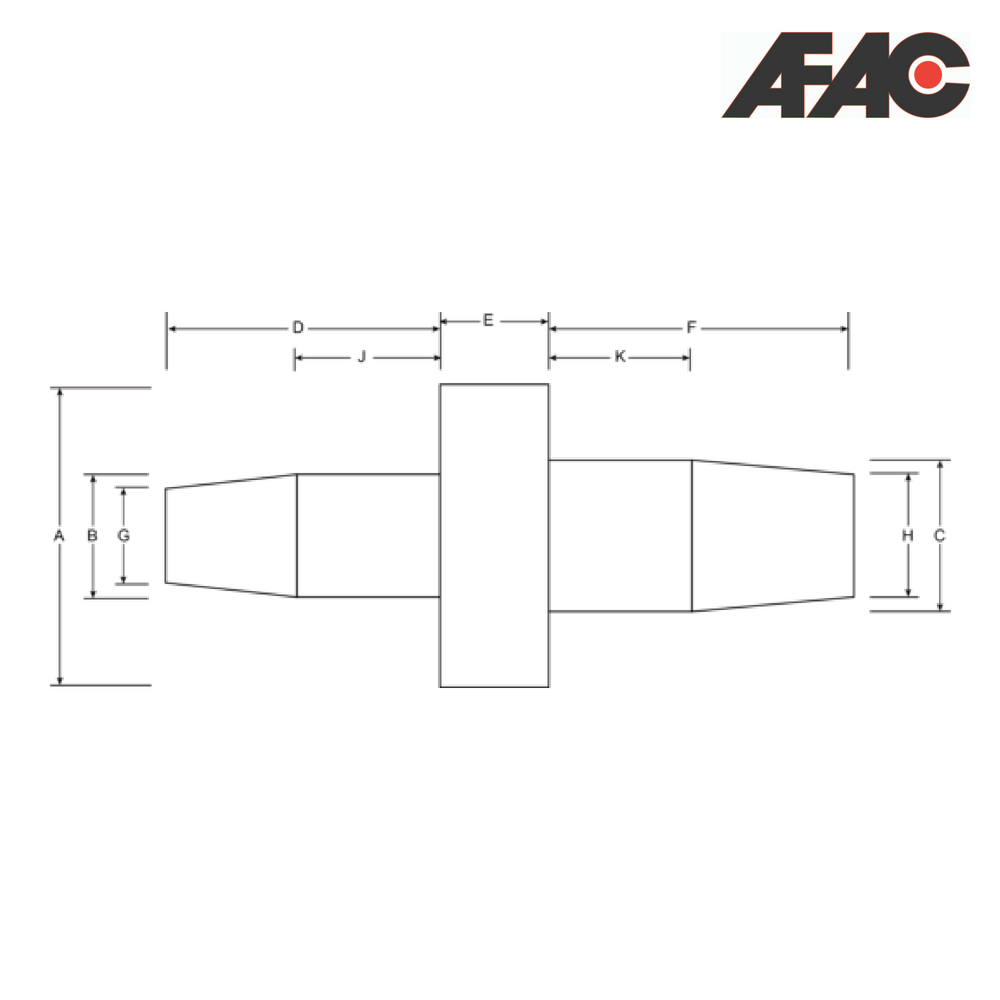

| Part No | ‘A’ | ‘B’ | ‘C’ | Weight |

|---|---|---|---|---|

| SI-02.6-03.3-06 | 6.4 | 2.62 | 3.3 | 0.27g |

| SI-02.8-03.7-07 | 7.0 | 2.80 | 3.70 | 0.32g |

| SI-03.1-06.4-08 | 8.1 | 3.15 | 6.40 | 0.77g |

| SI-03.2-06.5-15 | 15.9 | 3.2 | 6.5 | 1.62g |

| SI-03.3-05.3-13 | 12.7 | 3.3 | 5.3 | 1.00g |

| SI-03.3-03.6-06 | 6.4 | 3.3 | 3.6 | 0.38g |

| SI-03.3-09.5-13 | 12.7 | 3.3 | 9.53 | 1.72g |

| SI-03.4-04.0-08 | 7.9 | 3.4 | 4.0 | 0.52g |

| SI-03.5-05.0-09 | 9.5 | 3.35 | 5.05 | 0.73g |

| SI-03.5-04.5-13 | 12.7 | 3.56 | 4.57 | 1.01g |

| SI-03.6-06.4-13 | 12.7 | 3.6 | 6.4 | 1.20g |

| SI-03.6-06.4-16 | 15.9 | 3.6 | 6.4 | 1.63g |

| SI-03.5-06.4-16 | 15.9 | 3.56 | 6.05 | 1.63g |

| SI-03.6-04.6-08 | 7.9 | 3.6 | 4.6 | 0.59g |

| SI-03.6-04.6-06 | 6.4 | 3.61 | 4.57 | 0.48g |

| SI-03.6-04.7-09 | 9.0 | 3.6 | 4.7 | 0.57g |

| SI-03.9-05.0-06 | 6.4 | 3.9 | 5.08 | 0.49g |

| SI-03.9-06.1-08 | 7.9 | 3.94 | 6.05 | 0.76g |

| SI-03.9-06.0-09 | 9.5 | 3.94 | 6.05 | 0.88g |

| SI-03.9-09.9-13 | 12.7 | 3.9 | 9.9 | 1.79g |

| SI-04.5-05.7-09 | 9.5 | 4.5 | 5.7 | 0.77g |

| SI-04.5-05.7-10 | 10.0 | 4.5 | 5.7 | 0.92g |

| SI-04.5-04.5-06 | 6.4 | 4.57 | 4.57 | 0.54g |

| SI-04.5-06.0-06 | 4.6 | 4.57 | 6.05 | 0.68g |

| SI-04.5-05.0-07 | 7.0 | 4.57 | 5.08 | 0.60g |

| SI-04.5-05.7-08 | 8.9 | 4.57 | 5.08 | 0.60g |

| SI-04.6-05.1-09 | 9.5 | 4.6 | 5.1 | 0.81g |

| SI-04.5-06.3-09 | 9.5 | 4.57 | 6.35 | 0.96g |

| SI-04.6-05.1-13 | 12.7 | 4.6 | 5.1 | 1.11g |

| SI-05.1-07.0-09 | 9.5 | 5.0 | 7.0 | 1.12g |

| SI-05.3-06.7-12 | 12.5 | 5.3 | 6.7 | 1.30g |

| SI-06.0-06.3-13 | 12.7 | 6.05 | 6.35 | 1.42g |

| SI-06.4-06.4-09 | 9.5 | 6.4 | 6.4 | 1.17g |

| SI-06.7-16.3-30 | 30 | 6.75 | 16.3 | 7.59g |

| SI-06.7-19.4-30 | 30 | 6.73 | 19.43 | 8.50g |

| SI-06.9-09.5-09 | 9.5 | 6.99 | 9.53 | 1.67g |

| SI-06.9-09.5-13 | 12.7 | 6.99 | 9.53 | 2.14g |

| SI-07.1-08.7-17 | 17.0 | 7.1 | 8.7 | 2.63g |

| SI-08.4-08.4-20 | 20.0 | 8.4 | 8.4 | 3.13g |

| SI-09.6-10.7-21 | 21 | 9.6 | 10.7 | 4.74g |

| SI-09.9-11.6-13 | 12.7 | 9.91 | 11.6 | 3.05g |

| SI-10.9-11.6-24 | 24.0 | 10.9 | 12.7 | 9.65g |

| SI-14.0-17.5-20 | 20.0 | 14.0 | 17.5 | 7.0g |

| SI-14.0-18.8-24 | 24.0 | 14.0 | 18.0 | 7.77g |