Introduction

The electric vehicle (EV) market is set for exponential growth in the coming years, driven by increasing consumer demand, government incentives, and a global push towards decarbonization. This surge in EV adoption presents significant opportunities for the coatings industry, particularly for powder coatings. This article explores the role of powder coatings in EVs, their benefits, and the future growth prospects in this burgeoning market.

Market Overview and Growth Projections

Current and Future Market Trends

In 2022, approximately 8 million electric vehicles were sold out of a total of 80 million vehicle sales, indicating a penetration level of around 10%. By 2030, this penetration is expected to rise dramatically to 35-40%, with around 38 million EVs anticipated to be sold. This represents a compound annual growth rate (CAGR) of 15-20% over the next decade.

Regional Insights

- China and the EU: These regions are expected to lead the way, with EV penetration exceeding 50% by 2030.

- United States and India: Both countries are projected to achieve EV penetration levels of 25-30% by 2030, driven by stringent decarbonization targets and supportive legislation.

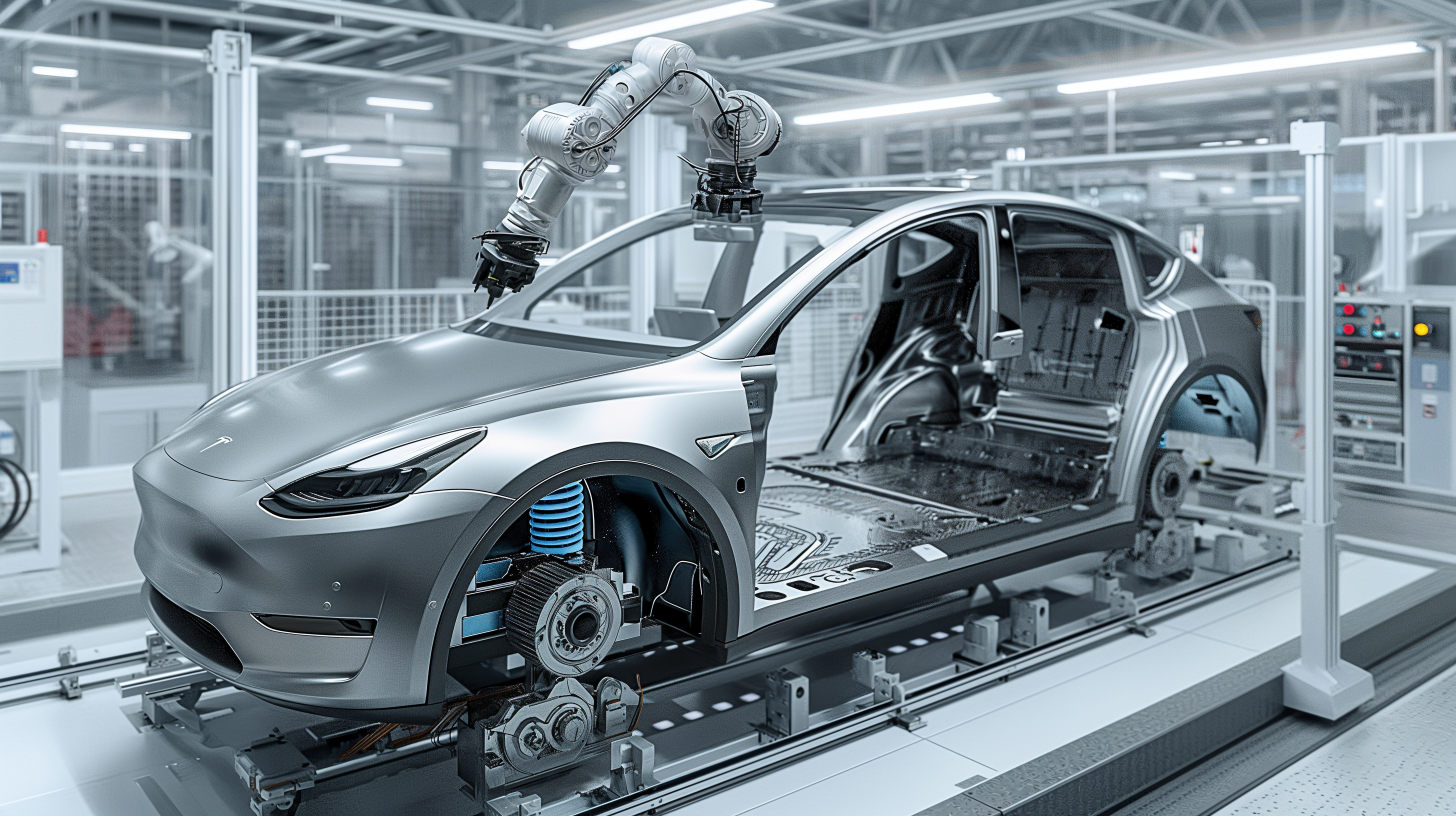

The Role of Coatings in Electric Vehicles

Increased Coating Content in EVs

Unlike internal combustion engine (ICE) vehicles, electric vehicles require significantly more coatings, nearly 2-2.5 times more in value terms. This increased demand is due to the unique requirements of EV components, particularly the battery packs.

Key Requirements for EV Coatings

- Fire Protection: EV batteries and charging points generate substantial heat. Fast chargers can push battery temperatures to 270°C within minutes, necessitating coatings that can protect against such extremes.

- Dielectric Protection: To prevent electromagnetic interference and arcing between metal parts, coatings with dielectric properties are essential.

- Thermal Management: Effective thermal management coatings are needed to maintain battery efficiency and longevity by managing temperature extremes.

Benefits of Powder Coatings for EVs

Toughness and Chemical Resistance

Powder coatings are known for their durability and resistance to chemicals. This makes them ideal for protecting various EV components from harsh environmental conditions.

High Dielectric Strength

Epoxy powder coatings provide excellent dielectric strength, making them suitable for critical EV components such as bus bars, stators, rotors, and battery pack covers. This protection supports the long-term performance and safety of the battery.

Single-Coat Application

While traditional ICE vehicles often require multiple layers of liquid coatings (primers, top coats, etc.), powder coatings can meet all requirements in a single coat. This includes corrosion protection, dielectric protection, weatherability, and impact resistance. This single-coat capability is particularly advantageous for new EV technologies and designs, offering cost and performance benefits.

Sustainability

Powder coatings are inherently more sustainable than liquid coatings due to their lack of volatile organic compounds (VOCs), minimal waste generation, and faster processing times. These environmental benefits align well with the green ethos of the EV market.

Real-World Applications and Case Studies

Application in Battery Packs

Battery packs in EVs are subject to high temperatures and potential chemical exposure. Powder coatings provide a robust protective layer that enhances the durability and performance of these battery packs.

Automotive Manufacturers Adopting Powder Coatings

Leading automotive manufacturers are increasingly turning to powder coatings for their EV production lines. For example, a major EV manufacturer has adopted epoxy powder coatings for their bus bars and battery covers, resulting in improved performance and safety.

Future Growth Prospects

Expansion in Emerging Markets

As EV adoption grows globally, particularly in emerging markets like China and India, the demand for high-performance coatings will continue to rise. These markets offer significant growth opportunities for powder coating manufacturers.

Innovation in Coating Technologies

Continued research and development in powder coating technologies will drive further advancements. Innovations such as nano-coatings and high-temperature resistant coatings will enhance the capabilities of powder coatings, making them even more suitable for advanced EV applications.

Regulatory Support

Government regulations aimed at reducing carbon emissions and promoting sustainable manufacturing practices will further boost the adoption of powder coatings in the EV market. Compliance with these regulations will be crucial for manufacturers looking to capitalize on this growth.

Strategic Opportunities for AFAC Ltd

Leveraging Technological Advancements

AFAC Ltd can capitalize on the growing EV market by investing in research and development to create advanced powder coatings that meet the specific needs of EV manufacturers. By staying at the forefront of technological innovation, AFAC Ltd can provide superior solutions that enhance the performance and safety of EV components.

Expanding Market Reach

Expanding into high-growth regions such as China, the EU, and emerging markets will allow AFAC Ltd to tap into new customer bases and increase market share. Establishing strategic partnerships with key players in these regions can facilitate market entry and growth.

Promoting Sustainability

With the increasing focus on sustainability, AFAC Ltd can differentiate itself by developing eco-friendly powder coatings that align with the environmental goals of EV manufacturers. Promoting the sustainability benefits of powder coatings can attract environmentally conscious clients and enhance the company’s reputation.

Strengthening Customer Relationships

Building strong relationships with EV manufacturers is crucial for long-term success. AFAC Ltd should focus on providing customized solutions, excellent customer service, and ongoing support to foster loyalty and drive repeat business.

Conclusion

The electric vehicle market presents a significant growth opportunity for the powder coatings industry. With the increasing demand for EVs and the unique coating requirements of EV components, powder coatings are set to play a crucial role in the future of automotive manufacturing. By understanding market trends, leveraging technological advancements, and promoting sustainability, AFAC Ltd can capitalize on the numerous opportunities in this dynamic market.

For more information about our powder coating solutions and services, visit AFAC Ltd.