Introduction to AFAC Ltd and Its Founders

Since its inception in 1980, AFAC Ltd has carved a niche in the metal finishing industry with its innovative masking solutions. The company was founded by Lee Mullins, a visionary who saw the potential in providing high-quality masking products to an industry in need. Over the past four decades, AFAC Ltd has grown exponentially, adapting to industry changes and technological advancements to maintain its position as a leader in the field.

The Early Days

Lee Mullins started AFAC Ltd with a clear mission: to offer reliable, high-performance masking solutions for the metal finishing industry. His dedication to quality and customer satisfaction quickly set the company apart. From humble beginnings, AFAC Ltd began to build a reputation for excellence, a reputation that would see it through many decades of growth and innovation.

Key Milestones Over the Decades

1980s: Foundation and Growth

In the 1980s, AFAC Ltd established its foundation in the market. The initial years were marked by steady growth as the company expanded its product range and built a loyal customer base. Lee Mullins’ hands-on approach ensured that the company stayed true to its values of quality and reliability.

1990s: Technological Advancements

The 1990s brought significant technological advancements to the metal finishing industry, and AFAC Ltd was at the forefront of adopting these new technologies. The introduction of advanced materials and manufacturing processes allowed the company to develop even more effective masking solutions, meeting the evolving needs of its clients.

2000s: Expansion and Diversification

The new millennium saw AFAC Ltd expanding its operations and diversifying its product offerings. The company began to explore new markets and applications for its products, including the consumer sector. This period of expansion was marked by the development of innovative products that set new standards in the industry.

2010s: Leadership Transition and Modernization

In the 2010s, AFAC Ltd underwent a significant transition in leadership. Ryan Mullins, Lee’s son, took over the reins of the company. Under Ryan’s leadership, AFAC Ltd embraced modernization, implementing state-of-the-art technologies and processes to enhance production efficiency and product quality. This period also saw a renewed focus on sustainability and eco-friendly practices.

Evolution of Products and Services

Initial Product Range

When AFAC Ltd was founded, its product range was relatively limited, focusing primarily on essential masking solutions for metal finishing. However, even in those early days, the company’s commitment to quality and innovation was evident.

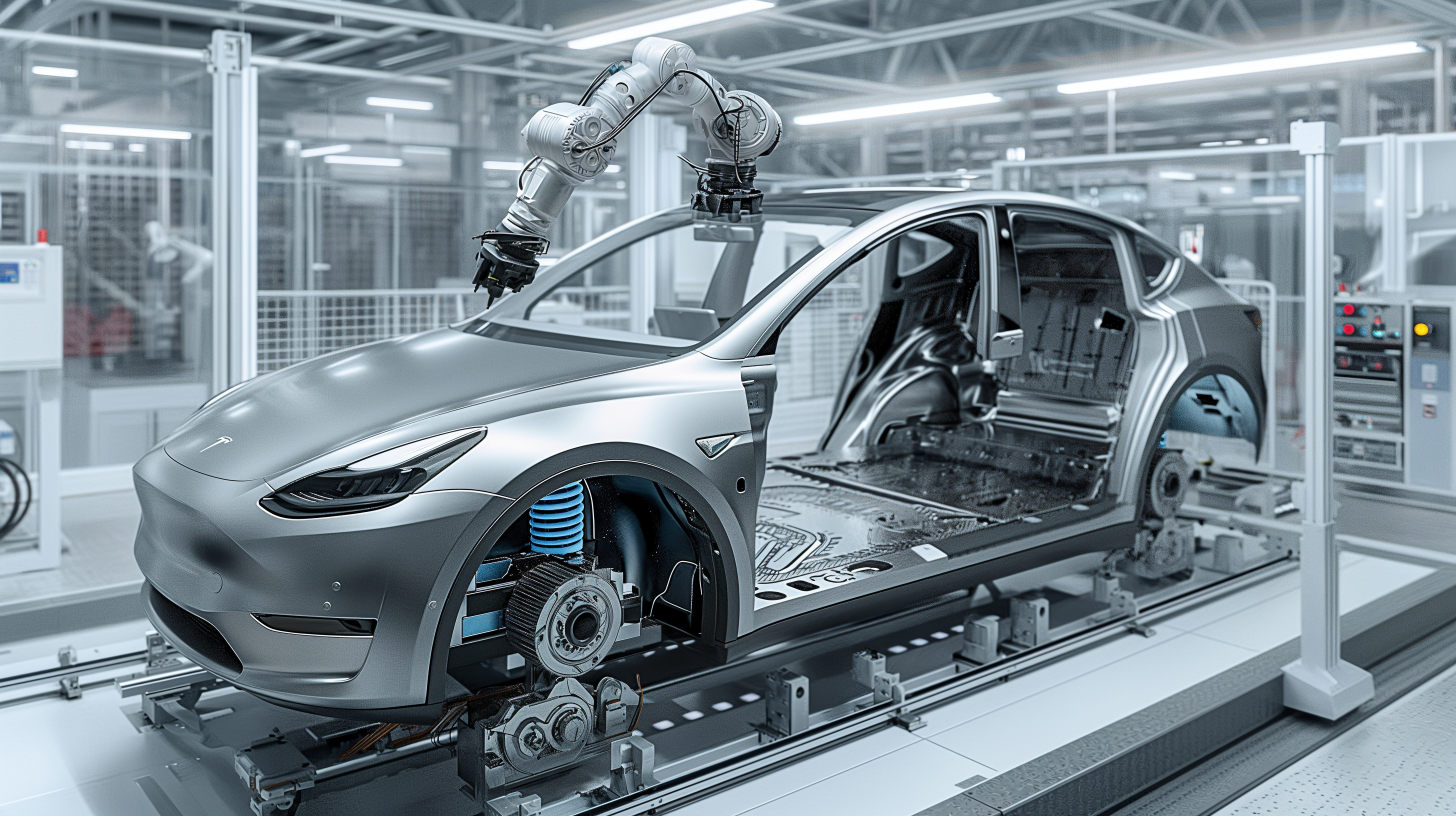

Technological Integration

As the industry evolved, so did AFAC Ltd’s product offerings. The integration of advanced technologies allowed the company to develop more sophisticated and effective masking solutions. These innovations not only improved product performance but also expanded the range of applications, catering to both industrial and consumer markets.

Current Product Portfolio

Today, AFAC Ltd offers a comprehensive portfolio of masking solutions designed to meet the diverse needs of its clients. From high-temperature masking products used in industrial applications to custom solutions for unique challenges, the company’s product range reflects its commitment to innovation and excellence.

Transition of Leadership

Lee Mullins: The Visionary Founder

Lee Mullins’ vision and dedication were instrumental in establishing AFAC Ltd as a trusted name in the metal finishing industry. His leadership style, characterized by a hands-on approach and a commitment to quality, set the foundation for the company’s long-term success.

Ryan Mullins: A New Era of Innovation

In the 2010s, leadership transitioned to Ryan Mullins, marking a new era for AFAC Ltd. Ryan brought a fresh perspective to the company, focusing on modernization and technological advancement. Under his leadership, AFAC Ltd has continued to thrive, maintaining its reputation for excellence while exploring new opportunities for growth.

Company Values and Mission Statement

Commitment to Quality

Quality has always been at the core of AFAC Ltd’s operations. The company’s stringent quality control processes ensure that every product meets the highest standards, providing reliable performance in even the most demanding applications.

Innovation and Excellence

AFAC Ltd is committed to innovation and excellence. The company continually invests in research and development to stay ahead of industry trends and deliver cutting-edge solutions to its clients. This focus on innovation has been a key driver of the company’s success over the years.

Customer-Centric Approach

A customer-centric approach is another cornerstone of AFAC Ltd’s philosophy. The company works closely with its clients to understand their unique needs and develop customized solutions that deliver exceptional results. This dedication to customer satisfaction has helped AFAC Ltd build long-lasting relationships with its clients.

Sustainability and Responsibility

In today’s world, sustainability is more important than ever. AFAC Ltd is committed to responsible manufacturing practices that minimize environmental impact. The company’s sustainability initiatives include the use of eco-friendly materials, energy-efficient processes, and waste reduction programs.

Looking Ahead: The Future of AFAC Ltd

As AFAC Ltd looks to the future, the company remains committed to its core values of quality, innovation, and customer satisfaction. With a strong foundation and a clear vision for the future, AFAC Ltd is well-positioned to continue its legacy of excellence in the metal finishing industry.

The company plans to expand its product offerings further, explore new markets, and leverage emerging technologies to deliver even more effective and sustainable solutions. Under Ryan Mullins’ leadership, AFAC Ltd will continue to lead the way in masking solutions, setting new standards for the industry.

Conclusion

AFAC Ltd’s journey since 1980 is a testament to the power of vision, dedication, and innovation. From its humble beginnings to its current status as a leader in the metal finishing industry, the company has always stayed true to its values. As AFAC Ltd celebrates over 40 years of excellence, it looks forward to many more years of success and innovation.

For more information about our products and services, visit AFAC Ltd.