Description

50.80mm Silicone Cap

Bakewell Silicone Caps are one of the most popular products chosen for covering pins, studs, rods and wires during finishing operations and assembly.

Silicone Rubber caps are suitable for many applications, from general protection to high temperature masking.

Silicone Rubber Caps – The Material

Manufactured from silicone rubber, Silicone Rubber caps or BAKEWELL CAPLUGS are ideal for masking during electro-static powder coating, stove enamelling, E-Coat, plating and anodising.

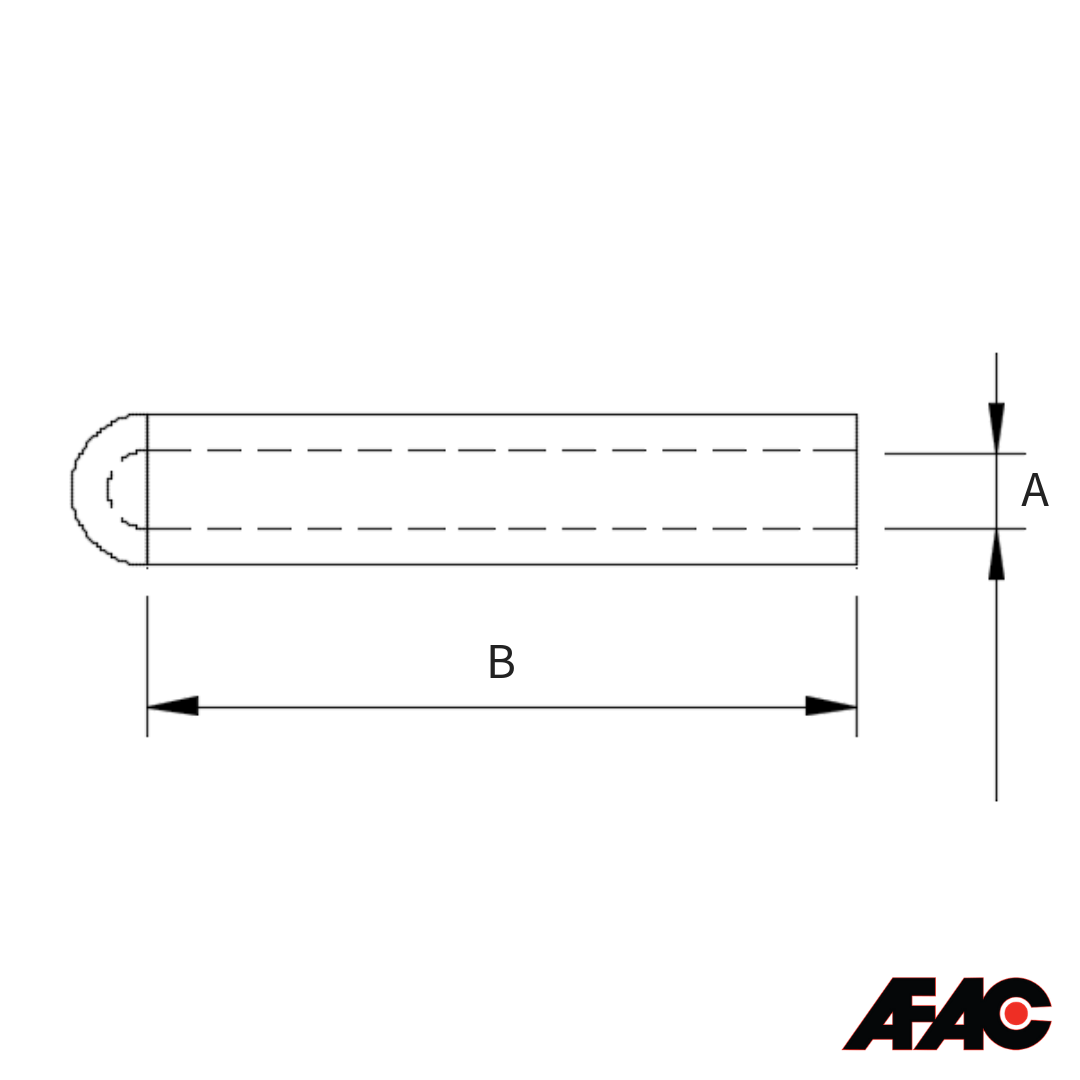

Silicone Rubber Caps Sizes

Popular sizes are colour coded to assist in selection and identification. The table shows the range available and what parts best suit the threads to be masked.

| Part Number | "A" (mm) | "B" (mm) | Colour | Add to cart |

|---|---|---|---|---|

| 074A-00.51-12BK | 0.51 | 12 | Black | £0.02Read more |

| 074A-01.80-25YW | 1.80 | 25 | Yellow | £0.03Add to basket |

| 074A-02.03-19OR | 2.03 | 19 | Orange | £0.03Add to basket |

| 074A-02.40-12RD | 2.40 | 12 | Red | £0.04Add to basket |

| 074A-02.40-19RD | 2.40 | 19 | Red | £0.04Add to basket |

| 074A-02.40-19YW | 2.40 | 19 | Yellow | £0.04Add to basket |

| 074A-02.54-12CL | 2.54 | 12 | Clear | £0.03Add to basket |

| 074A-02.54-25CL | 2.54 | 25 | Clear | £0.03Add to basket |

| 074A-02.54-38CL | 2.54 | 38 | Clear | £0.03Add to basket |

| 074A-02.80-12YW | 2.80 | 12 | Yellow | |

| 074A-02.80-19BL | 2.80 | 19 | Blue | £0.04Add to basket |

| 074A-02.80-25BL | 2.80 | 25 | Blue | £0.04Add to basket |

| 074A-03.50-25 | 3.50 | 25 | Clear | £0.05Add to basket |

| 074A-03.76-12GN | 3.76 | 12 | Green | £0.05Add to basket |

| 074A-03.76-19GN | 3.76 | 19 | Green | £0.05Add to basket |

| 074A-03.76-25GN | 3.76 | 25 | Green | £0.05Add to basket |

| 074A-04.00-25CL | 4.00 | 12 | Clear | £0.05Read more |

| 074A-04.37-25CL | 4.37 | 25 | Clear | £0.05Read more |

| 074A-04.37-38CL | 4.37 | 38 | Clear | £0.05Add to basket |

| 074A-04.57-25CL | 4.57 | 25 | Clear | £0.06Add to basket |

| 074A-04.70-25 | 4.70 | 25 | Clear | |

| 074A-04.75-12LL | 4.75 | 12 | Lilac | £0.06Add to basket |

| 074A-04.75-25LL | 4.75 | 25 | Lilac | £0.06Add to basket |

| 074A-04.75-38LL | 4.75 | 38 | Lilac | £0.06Add to basket |

| 074A-04.75-38CL | 4.75 | 38 | Clear | £0.06Add to basket |

| 074A-05.66-12CL | 5.66 | 12 | Clear | £0.07Add to basket |

| 074A-05.66-19BK | 5.66 | 19 | Black | £0.07Add to basket |

| 074A-05.66-25BK | 5.66 | 25 | Black | £0.07Add to basket |

| 074A-05.66-38BK | 5.66 | 38 | Black | £0.07Add to basket |

| 074A-05.90-25BK | 5.90 | 25 | Black | £0.07Add to basket |

| 074A-05.90-38BK | 5.90 | 38 | Black | £0.07Add to basket |

| 074A-06.60-25CL | 6.60 | 25 | Clear | £0.08Add to basket |

| 074A-07.49-25CL | 7.49 | 25 | Clear | £0.08Add to basket |

| 074A-07.49-38CL | 7.49 | 38 | Clear | £0.08Add to basket |

| 074A-07.90-25WH | 7.90 | 25 | White | £0.08Add to basket |

| 074A-07.90-38WH | 7.90 | 38 | White | £0.08Add to basket |

| 074A-08.64-25CL | 8.64 | 25 | Clear | £0.09Add to basket |

| 074A-09.50-25BN | 9.50 | 25 | Brown | £0.10Add to basket |

| 074A-09.50-38BN | 9.50 | 38 | Brown | £0.10Add to basket |

| 074A-10.31-25CL | 10.31 | 25 | Clear | £0.12Add to basket |

| 074A-11.58-25GN | 11.58 | 25 | Green | £0.12Read more |

| 074A-11.90-25GY | 11.90 | 26 | Grey | £0.12Add to basket |

| 074A-12.70-38LG | 12.70 | 38 | Green | £0.30Add to basket |

| 074A-14.27-20CL | 14.27 | 20 | Clear | £0.14Read more |

| 074A-14.27-38BL | 14.27 | 38 | Blue | £0.22Add to basket |

| 074A-15.87-38LB | 15.87 | 38 | Blue | £0.15Add to basket |

| 074A-17.45-16 | 17.45 | 16 | Clear | £0.14Add to basket |

| 074A-18.54-38CL | 18.54 | 38 | Clear | £0.30Add to basket |

| 074A-19.05-50CL | 19.05 | 50 | Clear | £0.35Add to basket |

| 074A-19.05-90CL | 19.05 | 90 | Clear | |

| 074A-50.80-50 | 50.80 | 50 | Clear | £1.20Add to basket |