Description

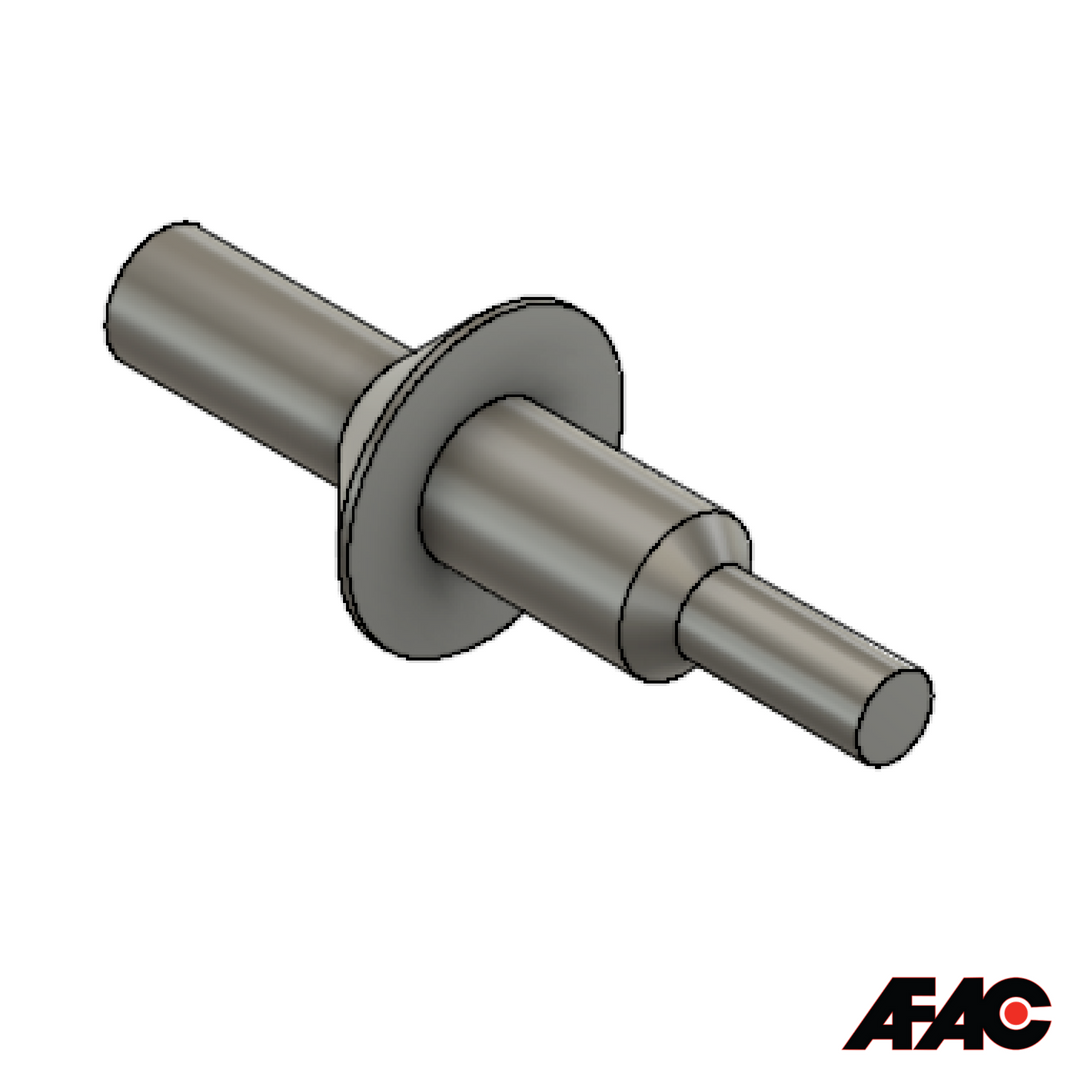

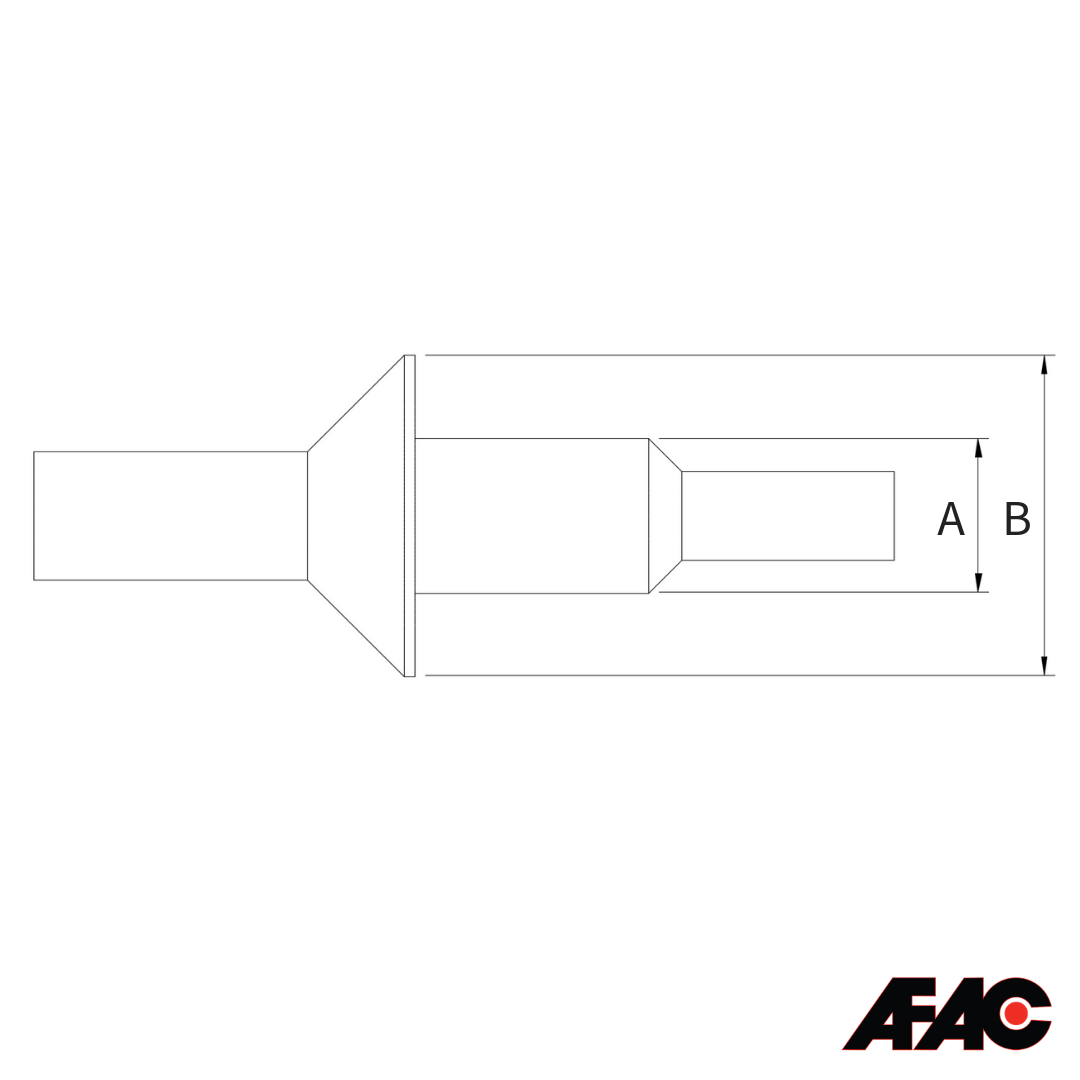

The Washer Pull Plug – Silicone Rubber Plug

| Product Number | ‘A’ Dia | ‘B’ Dia | Weight | |

|---|---|---|---|---|

| UMB-02.9-10.0 | 10.00 mm | 2.9 mm | 0.44g | |

| UMB-03.0-10.0 | 10.00 mm | 3.0 mm | 0.38g | |

| UMB-03.5-10.0 | 10.00 mm | 3.5 mm | 0.47g | |

| UMB-03.6-10.0 | 10.00 mm | 3.6 mm | 0.42g | |

| UMB-03.8-10.0 | 10.00 mm | 3.8 mm | 0.61g | |

| UMB-04.0-10.0 | 10.00 mm | 4.0 mm | 0.45g | |

| UMB-04.5-10.0 | 10.00 mm | 4.5 mm | 0.57g | |

| UMB-04.5-12.0 | 12.00 mm | 4.5 mm | 0.81g | |

| UMB-04.7-12.7 | 12.70 mm | 4.7 mm | 0.83g | |

| UMB-05.0-14.3 | 14.30 mm | 5.0 mm | 0.95g | |

| UMB-05.0-10.0 | 10.00 mm | 5.0 mm | 0.68g | |

| UMB-05.0-15.0L | 15.00 mm | 5.0 mm | 01.31g | |

| UMB-05.5-14.0 | 14.00 mm | 5.5 mm | 1.30g | |

| UMB-05.0-15.0 | 15.00 mm | 5.0 mm | 1.14g | |

| UMB-05.7-15.9 | 15.90 mm | 5.7 mm | 1.30g | |

| UMB-06.0-15.0 | 15.00 mm | 6.0 mm | 1.20g | |

| UMB-07.2-17.5 | 17.50 mm | 7.2 mm | 2.05g | |

| UMB-07.2-15.0 | 15.00 mm | 7.2 mm | 1.61g | |

| UMB-07.2-16.5 | 16.50 mm | 7.2 mm | 1.92g | |

| UMB-07.4-16.0 | 16.00 mm | 7.4 mm | 1.88g | |

| UMB-08.0-10.0 | 10.00 mm | 8.0 mm | 1.37g | |

| UMB-08.0-15.0 | 15.00 mm | 8.0 mm | 1.74g | |

| UMB-08.4-17.8 | 17.80 mm | 8.4 mm | 2.24g | |

| UMB-08.8-20.6 | 20.60 mm | 8.8 mm | 2.95g | |

| UMB-09.2-18.0 | 18.00 mm | 9.2 mm | 2.97g | |

| UMB-09.5-20.0 | 20.00 mm | 9.5 mm | 3.15g | |

| UMB-10.0-16.5 | 16.50 mm | 10.0 mm | 2.93g | |

| UMB-10.0-20.0 | 20.00 mm | 10.0 mm | 3.33g | |

| UMB-10.2-23.4 | 23.40 mm | 10.2 mm | 5.8 mm | 4.44g |

| UMB-10.9-20.0 | 20.00 mm | 10.9 mm | 3.72g | |

| UMB-10.9-28.5 | 28.50 mm | 10.9 mm | 8.47g | |

| UMB-11.0-20.0 | 20.00 mm | 11.0 mm | 5.0 mm | 3.90g |

| UMB-11.3-20.6 | 20.60 mm | 11.3 mm | 4.16g | |

| UMB-11.7-27.0 | 27.00 mm | 11.7 mm | 5.45g |

The Washer Pull Plug offer the means of masking the bottom of a counterbore, or face, where an uncoated area is required around a through hole. The Washer Pull Plug features a chamfered masking flange to allow coating right to the edge of the flanged portion. Manufactured from bakewell silicone rubber, the Washer Pull Plug will withstand stoving cycles up to 315•c, making the ideal for use in electrostatic powder coating, Cerakote, wet painting, plating and anodising processes.

The Washer Pull Plug are best fitted after any cleaning operations. The small diameter tail is passed through the hole in the component until the larger diameter reaches the hole. The tail is pulled, allowing the larger diameter to slide into the hole in the component, until the face of the masking flange seals against the face needing masking.

After processing, the Washer Pull Plug is simply pulled out using the spigot above the chamfered flange. Removal is best undertaken while the coating is still warm.

The Washer Pull Plug can also be used with a masking washer, which when fitted to the reverse end of the plug, will mask an area on the opposite end of the hole.